Durability & Strength — Hard-Anodized Aluminum

ID scanners in bars, restaurants, and casinos are prone to taking a beating. Whether someone drops it or bumps into it, the scanners are at risk of being damaged. At TokenWorks, we take preemptive measures to keep our scanners safe and protected to avoid damage. To protect the Microsoft Surface tablet and companion ID scanner that makes up IDentiFake, we designed a custom case made out of 1/8″ thick aircraft aluminum to house them in. The aluminum is hard anodized, which means it’s physically tougher and stronger than plain aluminum. This type of aluminum provides greatly improved wear, corrosion resistance, and heat resistance.

Benefits of Hard-Anodized Aluminum

- Tolerances The coating follows the contour of the part with uniform buildup, providing very close tolerance control. Holes 1/4 or larger in diameter will show coverage. It is also very effective on parts with unusual shapes, due to the excellent throwing power obtained in the hard anodizing process.

- Wear Resistance Hard anodized coatings are more than 10 times more wear resistant than ordinary anodized aluminum. Hard anodized aluminum exhibits only half the amount of wear that cyanide case hardened steel shows after 50,000 cycles of the standard Tabor abrasion tester.

- Hardness / Micro-hardness tests on hard anodized aluminum typical have values of 500 to 530 VPN. Micro-hardness is nearly independent of coating thickness up to 1.5 mils.

- Heat Resistance Hard anodized coated parts can withstand short exposures of temperatures up to 2000 degrees centigrade due to the inert nature of the coating.

- Thermal Properties Hard anodized coatings exhibit very low thermal conductivity and expansion but excellent thermal emissivity. At higher thickness, emissivity is comparable to a black body in terms of heat dissipation, offering little advantage to dying it black.

- Corrosion Resistance Hard anodized coatings typically pass the 1000-hour 5% salt spray test (ASTM B-117).

- Electrical Properties Hard anodized coatings are excellent electrical insulators, exhibiting electrical resistance on the same order of magnitude as glass and porcelain.

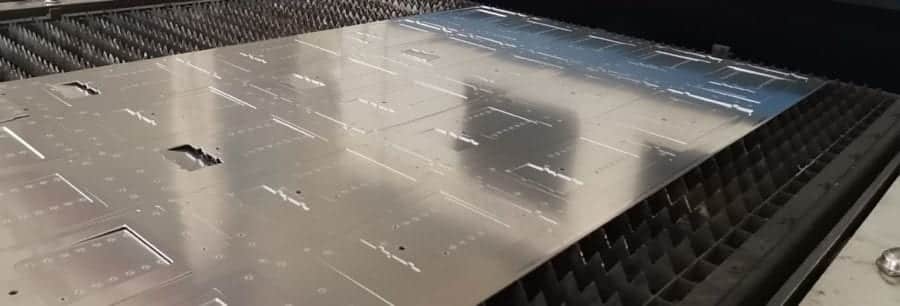

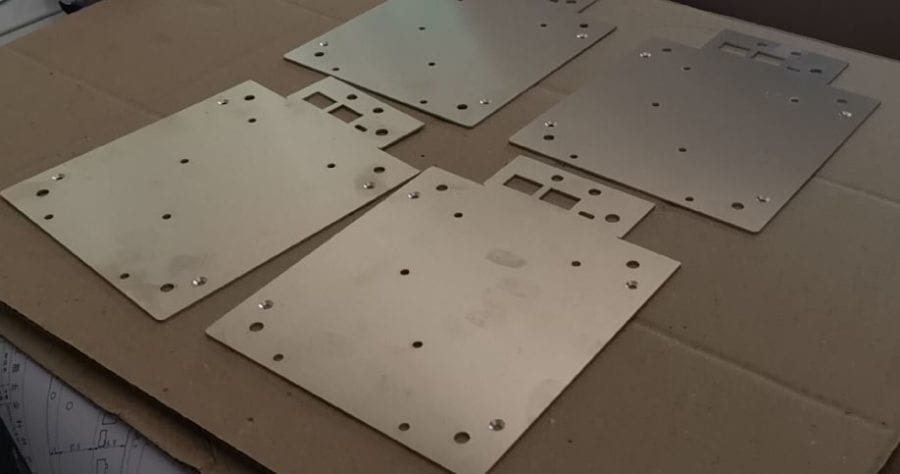

Take a look at the case production process in the photos below. This is before the hard anodized aluminum is cut and folded to accommodate the IDentiFake dimensions.

Protection and Anti-Theft

Besides physical damage protection, we also take measures on preventing theft. The ID scanner itself is housed on a sliding drawer which can be locked in place with a security screw while in operation. The entire unit can be secured in place with a laptop locking cable, preventing anyone from walking away with it.

As you can see, we value durability, strength, and protection when it comes to the IDentiFake’s design process. To learn more about IDentiFake, click here or give us a call at 914-704-3100.